(주)성곡

전체메뉴

(주)성곡

ESD Tray

What is ESD Tray?

Electrostatic discharge +This is the tray optimized for the prevention of infection by alien substances(dust and etc.), and SUNGGOK's ESD tray is categorized into the following three according to the surface resistivity (Ω) in accordance with the US Military Standard.

Anti-static tray

-

Surface resistivity(Ω/cm)

1010 ≤ Rs ≤ 1011 Ω/Sq

-

Electrification

Attenuate immediately after charging with electricity

-

Application field

Anti-static

Static Dissipative tray

-

Surface resistivity(Ω/cm)

106 ≤ Rs ≤ 109 Ω/Sq

-

Electrification

Barely charge with electricity

-

Application field

Anti-static / Prevent power storage

Conductive tray

-

Surface resistivity(Ω/cm)

Rs ≤ 10z5 Ω/Sq

-

Electrification

No charge with electricity at all

-

Application field

Electromagnetic shield

Comparison of raw material property according to ESD function realization method

-

Realization method

Spray surfactant on the sheet or the tray and dry it

-

Surface resistance

1010 ~ 1011

-

Advantage

○ Low cost

○ Simple process -

Disadvantage

○ ESD effect is inadequate

○ Migration generated

○ Durablity ↓

○ Low recyclability

-

Realization method

Add the blended electrical conductive carbon compound to the raw material, produce sheet and mold it using tray

-

Surface resistance

103 ~ 109

-

Advantage

○ Low cost

○ Successful ESD effect

○ ESD durability ↑ -

Disadvantage

○ Black dust generated

○ Limit in embodying colors

-

Realization method

Blend BlendIDP(Conducting polymer) and add it to the raw material, produce sheet and mold it using tray

-

Surface resistance

105 ~ 109

-

Advantage

○ Equal ESD effect

○ ESD durablity ↑ -

Disadvantage

○ The highest cost

○ Dust can be generated

-

Realization method

Coat the surface of the raw material sheet with transparent IDP(conductive high polymer) using the roll coating method

-

Surface resistance

105 ~ 109

-

Advantage

○ No migration

○ No dust -

Disadvantage

○ Relatively high cost

○ ESD durabiliy ↓

Main products

-

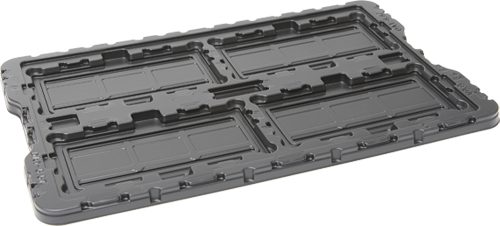

TRAY for transporting small and medium-sized modules

(Mobile, tablet, etc.)

-

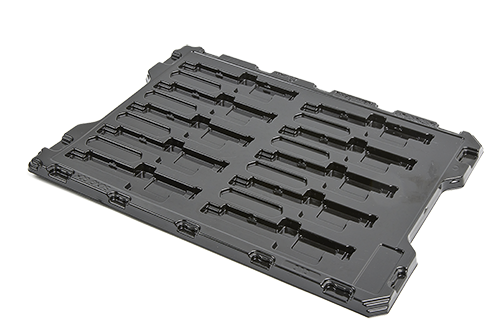

TRAY for transporting electronic parts

(PCB, CONNECTOR etc.)

-

Auto parts TRAY

-

For mobile cell process

-

Other products